In order to have a perfect

crystal look on acrylic piece, POLISHING is a MUST process. Acrylic is a

non-scratch proof plastic sheet. In order to make the perfect look after

scratches, generally, the surface can be touched up and polished to recover

it's original look.

The recommended way to clean

scratches from acrylic plastic is to buff out the scratches

with fine-grit sandpaper or a buffing machine and buffing polish. However,

there are more then 1 process that can make the acrylic back to it's original

look. Flame polishing is the technique of using a heat

source, generally an open flame, to melt and thereby polish the edge of a

piece of plastic. For reefing, this is usually most applicable to sumps. If

done correctly the finished result resembles an edge that is as clear as the

original acrylic.

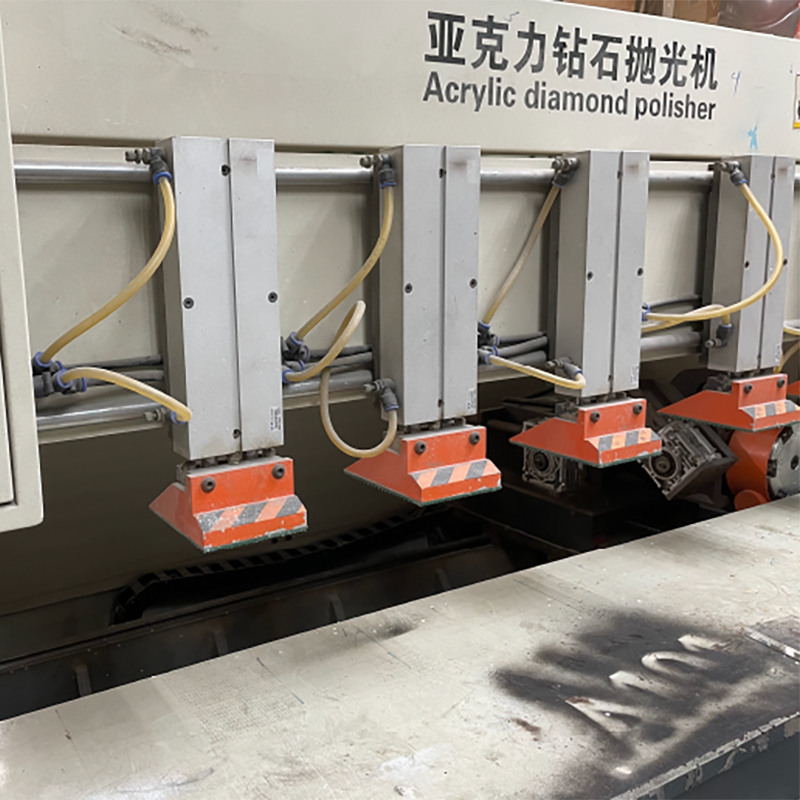

For polishing edge, commonly will

have the same process as traditional way, such as sandpaper polishing or flame

polishing. With the latest technology, ASM is providing a more effective and

efficient service for polishing edge by introducing Diamond Polishing service

into our rack of service.

A diamond edge polisher uses sharp diamonds, rotating

very quickly, to polish the edges of the acrylic material. This can result in

unbeatable smoothness on your surface. However, it’s important to keep in mind

that an acrylic diamond polishing machine will only work on straight or sloping

sides. So a diamond polish treatment cannot be used to produce rounded corners.